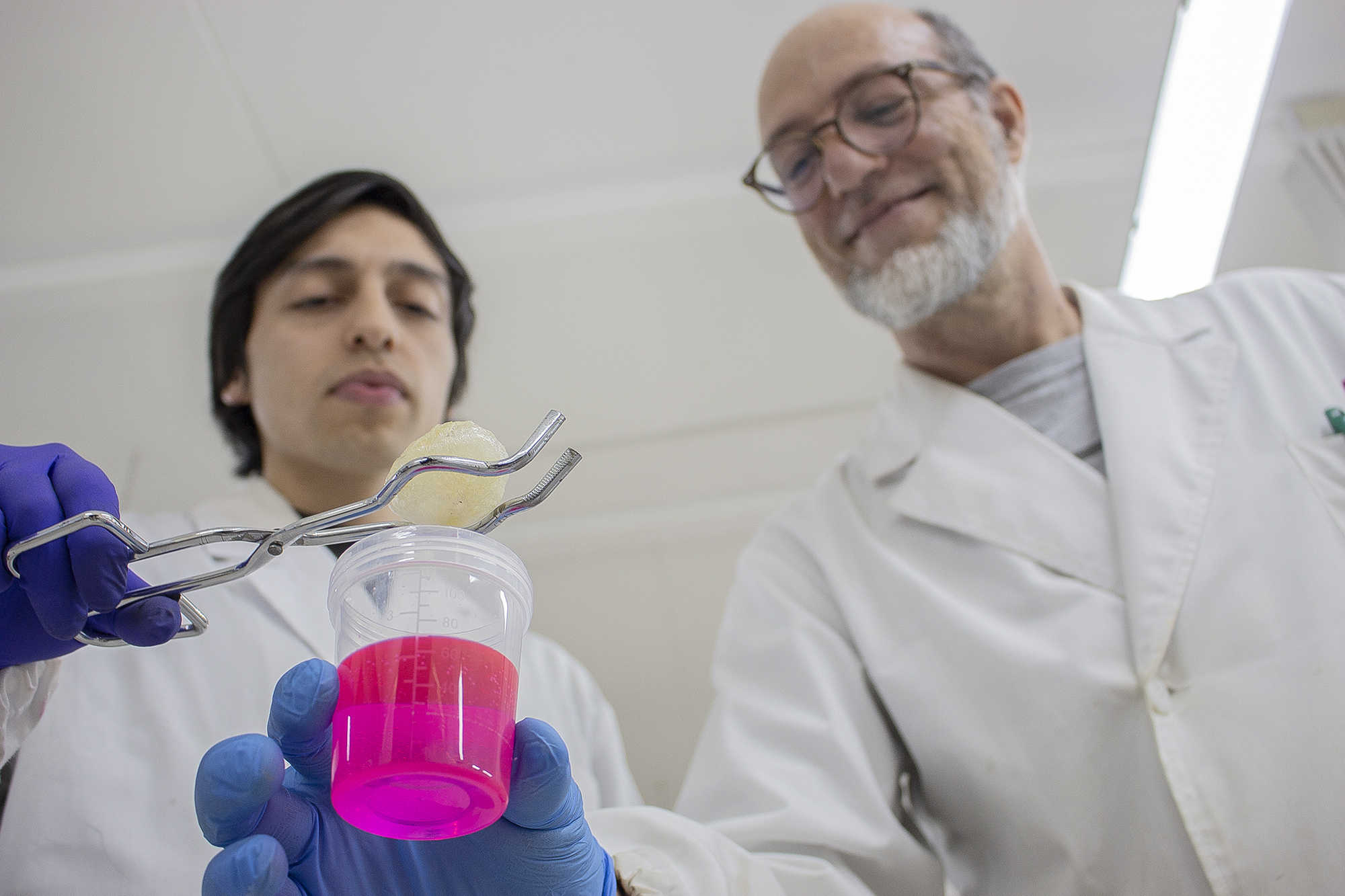

In the polymer laboratory Institute of Chemical Sciences From the Austral University in Chile, Dr. Ignacio Moreno and Mario Estrada have developed a new polymeric material, which can be used to absorb pollutants from water, such as, for example, dyes used in clothing or discarded antibiotics, whose chemical components (with which the material is formulated) are Accelerate the absorption of pollutants and stimulate their decomposition with light.

“This means that after the contaminant is absorbed from a water body, the material can be removed, left to dry in the sun, washed in a controlled environment (and in a low quantity), and reused,” said Dr. Ignacio Moreno, one of the researchers. One of the authors of the research that was published to the scientific community in the Journal of Chemical Engineering, one of the most important journals in this specialty.

According to scientists, these results will represent progress in addressing the problem of water pollution, as industries such as aquaculture, textiles or mining generate wastewater; In this sense, the authors point out that besides removing pollution, we can even “recover some useful materials, including rare earth elements,” says the researcher.

“We are conducting studies to manufacture balls that can be thrown into water and then collected with a net, to disinfect large bodies of water, such as sedimentation ponds or even lakes. “It is also possible to make filters to clean polluted water in a continuous flow, such as at the outlet of a complex or even a river,” Moreno said.

When asked about the format of this new material, the researcher explained that it could be presented in several presentations.

“They can be like particles made of very small sheets, as well as larger, more porous objects, as if they were pieces of foam from which mattresses are made. The basic requirement is that they have a large surface area in relation to volume; For this reason it is important that the material has pores, so that the contact surface increases.

the operation

Scientifically speaking, the new material is a polymer; More profoundly, it is a very large molecule, so large that it has no fixed size; Which consists of smaller molecular chains, and thus the number of links in the chains changes. It can be from a few tens to several thousand links per chain.

“When you see and touch a plastic cup, it is made of polymers, of molecular chains, some larger and others smaller, and from a mixture all the properties useful to us are obtained, such as elasticity, hardness, formability, etc.”

The polymer with which these materials are made was developed in 2019. In the midst of the pandemic, chemists were pioneers in returning to laboratories in person under tight security. With this effort, at the end of 2020, the material was completed and its applicability was proven.

During 2022 and 2023, other manufacturing options were explored, with a slight change in formulation to improve performance (seeking more frontiers), such as mechanical properties to better withstand field working conditions, and selectivity for its applications.

“For example, to be able to selectively extract rare earth minerals in mining, which are absolutely essential for the manufacture of all kinds of electronic materials that we use daily such as batteries, phones, satellites, etc.,” says the scientist. UCh Chem.

When asked about the results, the scientist emphasized the following:

“Yes, the results are surprising and that is why they have been published in a high-impact and demanding journal. We hope that these are not the only surprising results that we have been able to publish, also in other fields. This is because the initial hypothesis is very general: we use molecular interactions that make it possible, e.g. “For example, the DNA molecule as a double strand, to form materials with amazing properties in every field we can imagine. With this determination we hope to win a Nobel Prize one day.”

“Creator. Devoted pop culture specialist. Certified web fanatic. Unapologetic coffee lover.”